There is something beautiful about timber rainscreen cladding, and it’s especially striking when it extends seamlessly to the pitched roof areas. Simple building lines, the natural hue of timber, hidden gutter detailing and the neatly trimmed window reveals are just some of the aspects that makes these projects stand out from the crowd. But, getting the detailing right needs some careful consideration, so we have highlighted some of our key considerations in this blog for your benefit.

When thinking about rainscreen cladding for non-vertical areas such as pitched roofs, there are five main points to consider.

- The roof construction

- The waterproofing layer

- The connection method

- The cladding supporting structure

- The cladding material

Lets look at each of these points in more detail…

1. The roof construction

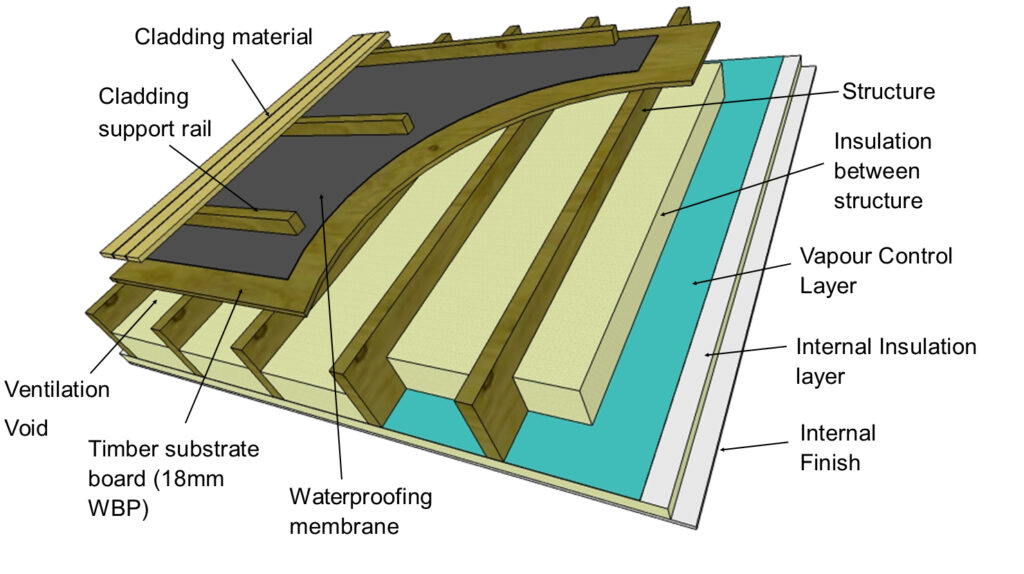

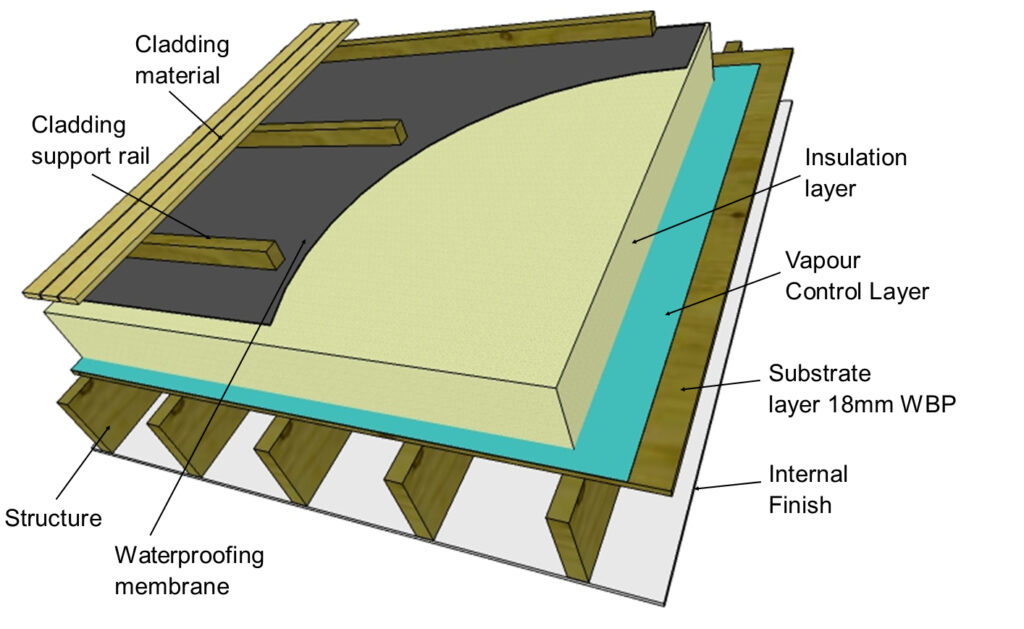

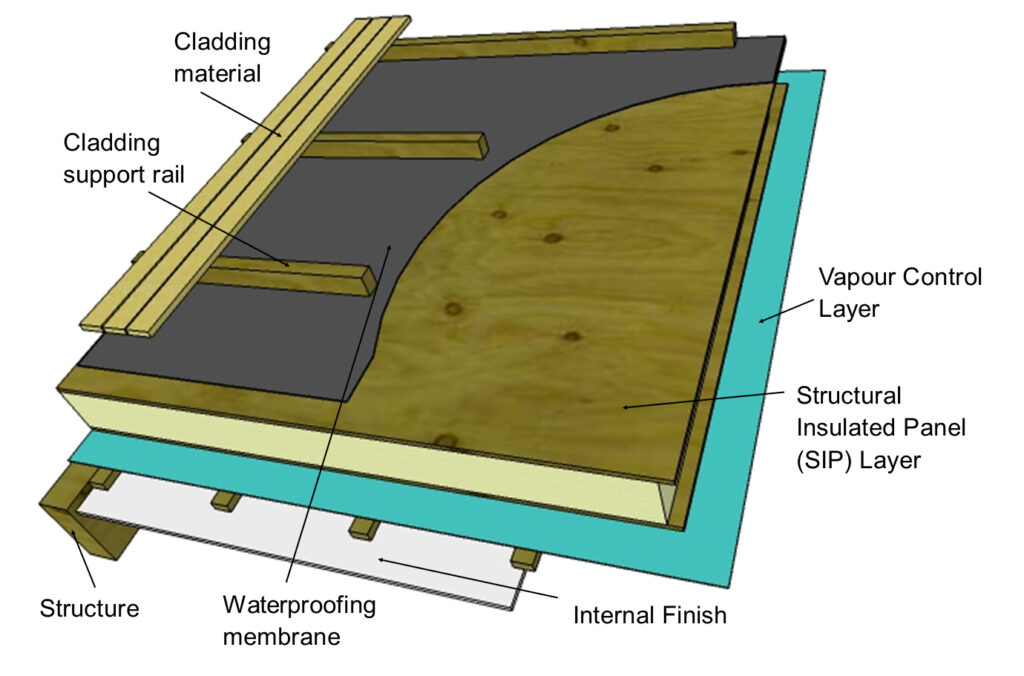

As the roof covering below the rainscreen cladding will form the waterproofing layer, the roof build-up could be similar in detail to a flat roof construction but pitched to suit the project. Cold or warm roof constructions can be utilised or SIPs. Each have some pros and cons.

Cold roof – Cold roofs have a timber deck directly below the waterproofing layer which makes getting a connection to the structure easier but remember that cold roofs also need to be ventilated below the roof deck in accordance with BS5250.

Warm Roofs – Warm roofs normally have a layer of insulation directly below the waterproofing layer which is laid on the roof deck or substrate. Fixing to a warm roof means the fasteners need to extend through the insulation layer to connect with the roof deck or substrate. Care needs to be taken to minimise thermal bridging and to make sure the insulation is not adversely compressed.

SIP Roofs

Structural Insulated Panel (SIP) roofs have the insulation sandwiched between two layers of timber. This brings the benefits of both a cold and warm roof, however particular care should be taken with the VCL. It is most important that there is no moisture in the roof build-up as this can lead to timber decay and premature roof failure. Fixing of the rainscreen cladding is usually connected to the outer skin of the SIP. Obviously its impotant that this layer is fixed to the structure (not just bonded) and as this is sometimes a thinner layer of timber, care needs to be taken to ensure that it will provide the necessary pull-out resistance for fixings made to it.

2. The waterproofing layer

As always, the waterproofing layer is the vital element in the application of timber rainscreen cladding. Most types of membranes can be used successfully – single ply, bitumen, EPDM and GRP. The main criteria is that the waterproofing layer has a warranty to suit the design life of the project.

3. The connection method

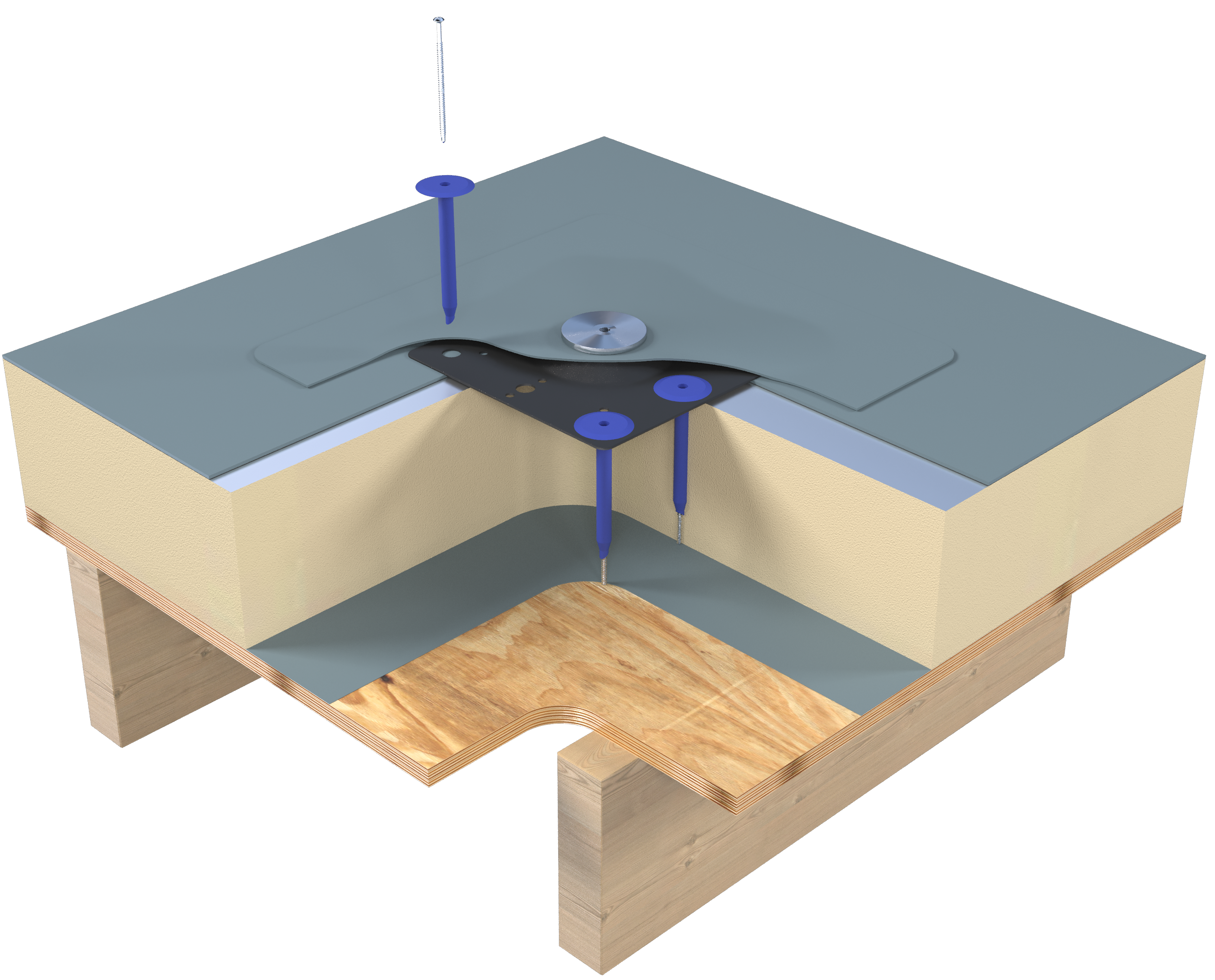

The connection between the rainscreen cladding and the building structure (whilst maintaining the integrity of the waterproofing layer) is undoubtedly the hardest part of the jigsaw. There are a few issues to consider.

- Loads on the structure – Obviously, the application of rainscreen cladding will produce load factors on the building elements it is connected to. In the main, these loads will be comprised of the following;

- The weight load of the cladding and support system.

- Wind load – this is extra to the weight load and is imposed by wind pushing or pulling against the rainscreen. This in turn is transferred back to the structure through the connection points that are used.

- Snow/wet material loads, again this is extra to any static weight load and occurs should the cladding be overlaid with snow or prolonged periods of wet weather can cause the cladding to become saturated with moisture making it heavier.

- Lateral loads – caused by gravitational force of the cladding down the roof slope, or expansion and contraction of the timber from season to season.

- Transfer of the load or forces – It’s important that any load is transferred to the structure and not just to the membrane or through the membrane. Some fixing methods that have been used in the past rely on a ‘membrane-to-membrane’ bond to secure a timber block or profile to the roof. This means that the various loads are transferred to the membrane. This is a potentially dangerous situation as membrane is not designed for this and can cause the membrane to tear over time. Further, where membrane is adhered to foil faced insulation, tests have shown that the foil face can separate from the insulation material, leaving the membrane and cladding unsecured.

- Multiple connections – Often in a rainscreen cladding situation multiple connections to the roof structure are required. It’s important to minimize thermal transfer through the fixings over the whole roof to maintain the design U-Values.

- Fire – Notwithstanding point 3, connection through to the structure should include some direct (metal) fixings. Installations relying on a membrane-to-membrane connections or using just plastic thermally broken fixings alone, means that should the connection be subjected to fire, the connection to the structure could be lost as the membrane or plastic parts melt in the heat, leaving the cladding free to fall and endangering persons below.

- Quantity – One of the key questions is how many connection points will be needed to hold the cladding in place. Normally this will need some input from a structural engineer, but the answer will be broadly governed by four factors.

- The location of the project, height above sea level and the associated wind and snow loads.

- The strength of the connection detail and its resistance to weight, uplift and shear loads.

- cThe strength of the cladding support rail – i.e. the centres at which this rail will need supporting (obviously the weaker the rail, the more often it will need supporting).

- dThe strength of the cladding material and the regularity at which it needs fixing to a cladding support rail.

4. The cladding support structure

Cladding support rails provide the connection between the external timber cladding and the connection points to the roof. These rails are often made from a treated timber bearer but aluminium, and even stainless-steel options, are available. The rails normally sit above the roof membrane level ensuring it can drain freely. Points to consider in the fixing of these rails should take into account the following factors.

- Longevity of the detail

- Overall build-up / height of the system above the membrane

- Overall weight of the cladding system

- The fixing interface between this rail and the building structure

- The expansion and contraction of the rail system.

- The cladding material

5. The cladding material

Given that the underlying structural arrangement is available, and an appropriate supporting system is in place, then the selection of the external cladding material is yours to choose… be creative, this is your project! Don’t let the waterproofing hold back your creativity..!

To find out how Nicholson can help with your rainscreen cladding projects take a look at the ROOFTRAK range or click on the images below to view some of our rainscreen projects.

Nicholson can also provide an online product presentation containing more details around the specifics detailed in this blog. Feel free to contact us for more information

The ROOFTRAK-IFP Integrated Fixing Point system has been developed specifically around the challenging scenario of providing a connection to the building structure whilst maintaining 100% integrity of the weathering membrane. There are different fittings available to provide for most types of roof construction and the IFP system is compatible with all roofing membranes.