When it comes to installing solar panels on a membrane covered roof there are different ways of getting the job done. This blog explores the pros & cons of different methods available. Before we go too much further, its helpful to understand the roof constructions and some of the terminology that is relevant to this subject.

Types of membrane roof

Membrane covered roofs – This is a flat or pitched roof that has a waterproof membrane covering. Some of these generic membrane types are listed below;

Single Ply – A single layer of plastic membrane, normally PVC or TPO, or rubber EPDM type sheet material. Joints are either made by welding with a hot air gun or with vulcanising/adhesive strip joints

Bituminous membrane – A single layer or multiple built-up layers of bitumen membrane. Typically, the top layer has a mineral coating to provide protection from foot traffic and exposure to direct sun light. Joints are made by heating the underside either with a gas torch or hot air gun.

Liquid applied membranes – a liquid system that is applied to the roof area and cures to form a waterproof membrane.

Most of these membrane systems can be used to waterproof both flat and pitched roof structures. A flat roof is classified as having a pitch of 10 degrees or less whilst a pitched roof has a pitch of 11 degrees or more.

Types of roof construction

There are many different types of flat roof construction, but the three main ones are as follows;

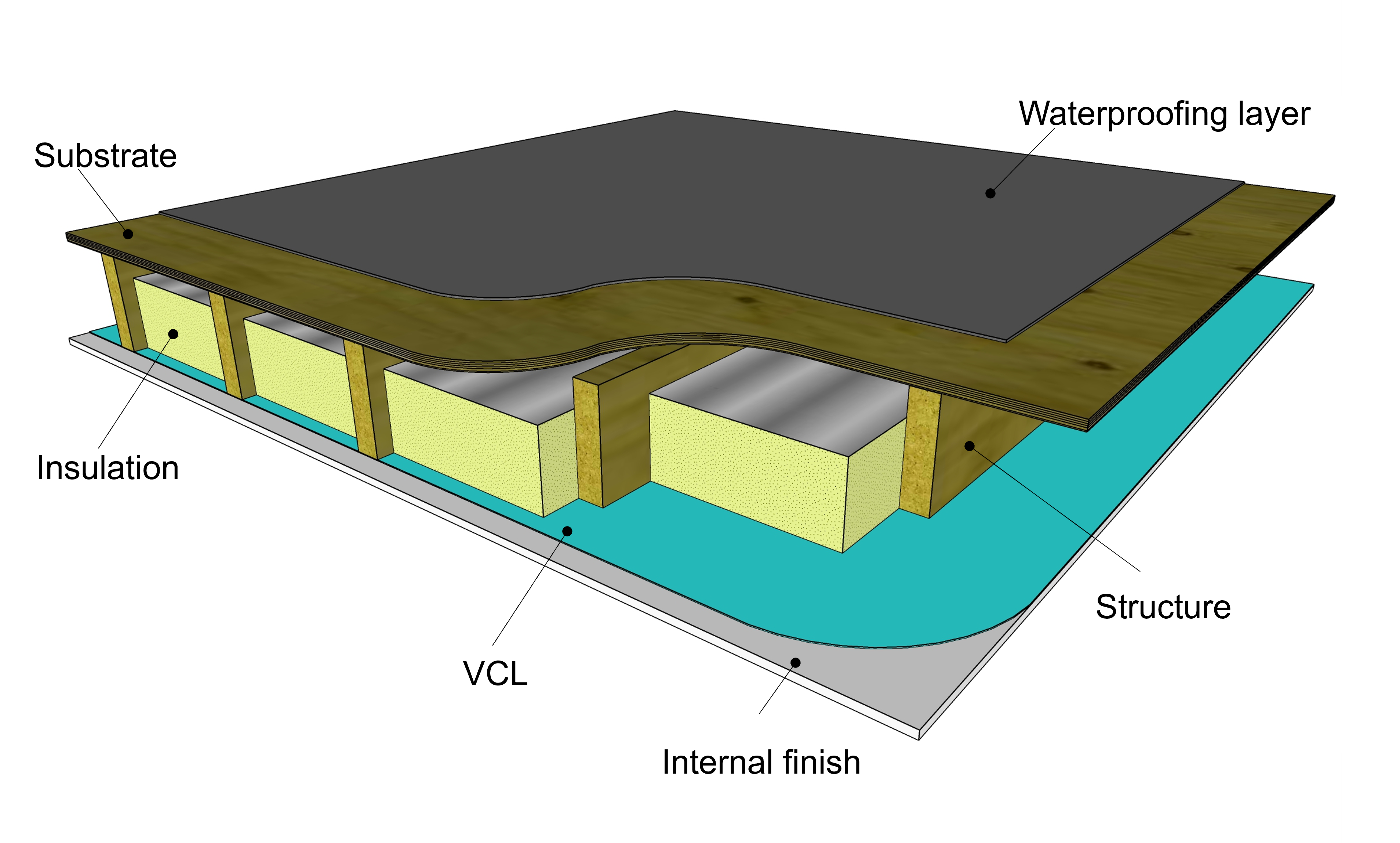

Cold Roof Construction – Typically cold roofs have a ventilated timber roof deck (substrate) directly below the membrane. Insulation is normally between the structure/rafters and the vapour control layer is close to the internal finishes. Used mainly for flat roofs.

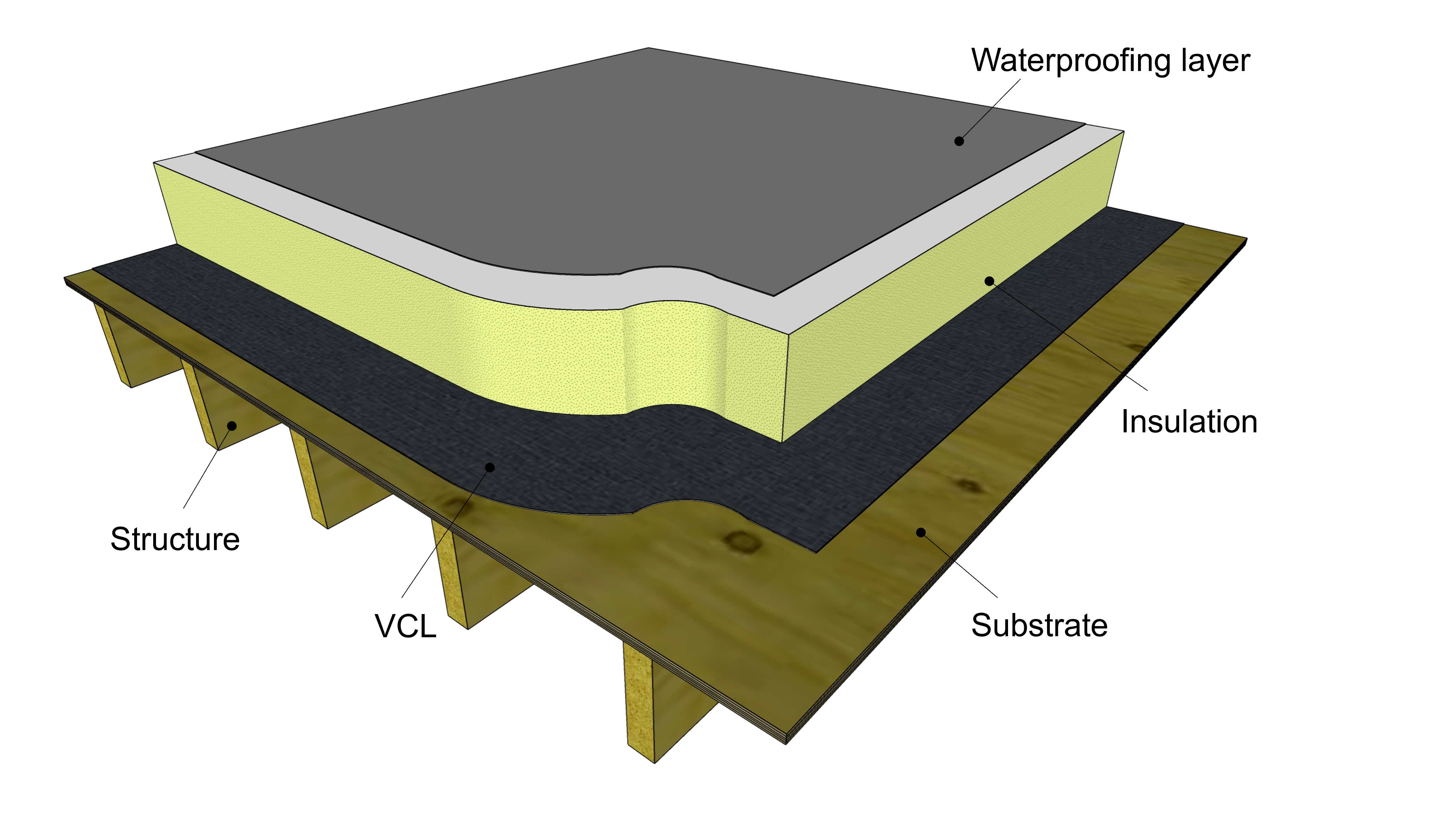

Warm Roof Construction – In a warm roof construction, insulation is directly below the membrane. Below the insulation is the VCL and supporting structure – typically a timber board, profiled steel decking or concrete. Used on flat and pitched roofs.

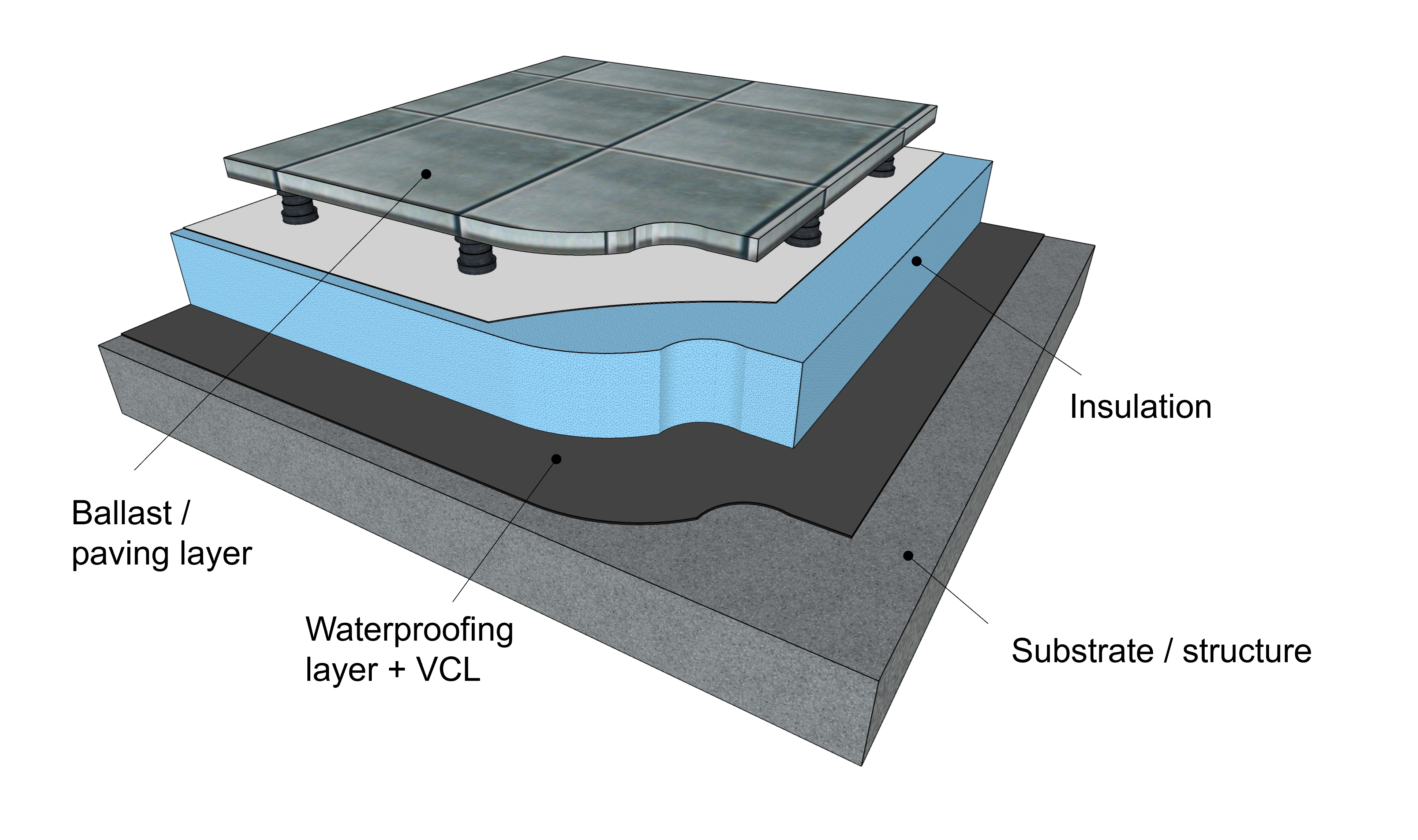

Inverted Roof Constructions – Inverted roof constructions have the waterproofing layer underneath the insulation and is sometimes called an upside-down roof. Because the insulation is exposed and often wet, these roofs normally have a deeper insulation layer. Used only on flat roofs.

Ways to fix Solar PV to the roof structure

So now we have looked at the roof structure and the roof coverings we can look at the different ways of mounting solar on the roof. Obviously, anything fixed to the roof needs to meet certain criteria;

1. It must not compromise the integrity of the waterproof covering

2. It must not be able to move or blow off

Solar panels are predominately mounted on a supporting framework. The interface between the support framework and the roof covering is critical and if not taken care of correctly can cause damage to the roof membrane and potentially the structure as well.

There are three main ways to mount the solar framework to the roof;

1. Ballasted (weighted) Installation

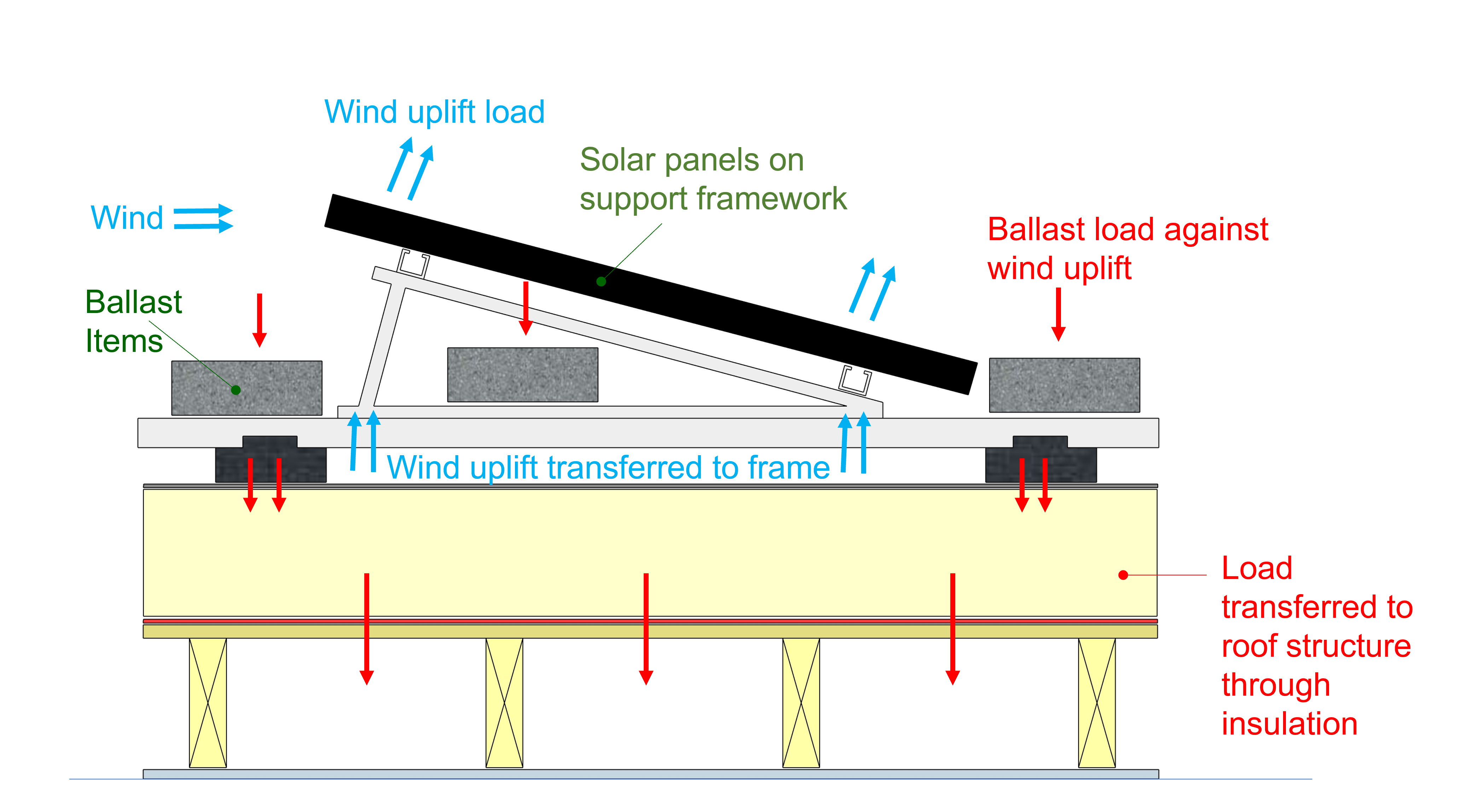

In a ballasted installation, the PV array is not fixed to the roof but is held in place by weights, often concrete blocks. A calculation is made for the ballast weight required to hold the PV array on the roof, so that even in windy weather the array will not move or blow off the roof. The calculation is dependent on the building location, the height of the roof, whether there is a parapet and the angle of the solar panels. The greater the wind uplift the more ballast is required.

Advantages

Disadvantages

- No penetration of / fixing through the waterproofing membrane

- Solar contractors can undertake the whole installation – no roofing contractor necessarily involved

- Often, a cheaper installation

- No mechanical connection to the building means there is a possibility of movement in very strong winds

- Not suitable for taller buildings over 20m

- Damage to the roof can occur between the ballast points and roof membrane due to small cyclical movements

- Greater load imposed on structure

- Load imposed on insulation in a warm roof structure

- Only suitable for very low pitch roofs

- Not suitable for compressible (mineral) insulation

- May not be suitable for buildings adjacent to train rail line

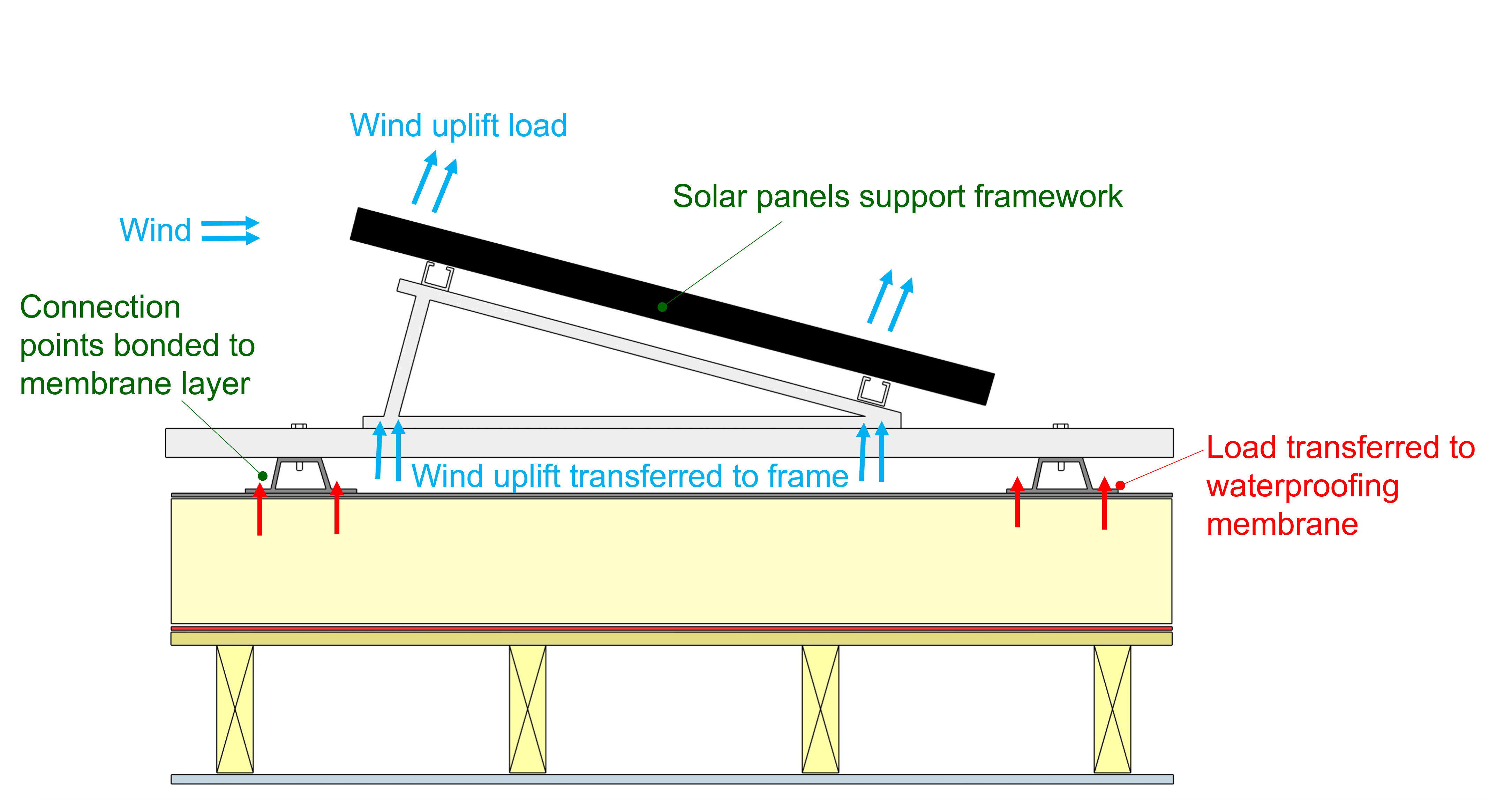

2. Bonded Installation

In a bonded installation the solar array is secured to the roof by a small console or rail that is heat welded or bonded to the roof covering. Wind uplift loads are transferred to the roofing membrane, which in turn is bonded to the substrate or structure. In a warm roof construction, there may well be insulation also within the bonded layers.

Advantages

Disadvantages

- No penetration or fixing through the waterproofing membrane.

- Can be installed on shallow pitched roofs

- No ballast so less weight on structure

- Wind uplift loading is transferred to the roofing membrane. This can cause delamination and potential tearing of the waterproofing membrane resulting in the array not being secured. This will cause water ingress.

- Can cause delamination between the roof membrane and the insulation.

- Roofing contractor is required to install the system.

- Not suitable for steeper pitched roofs

- Not suitable for mechanically fixed or ballasted membrane installations

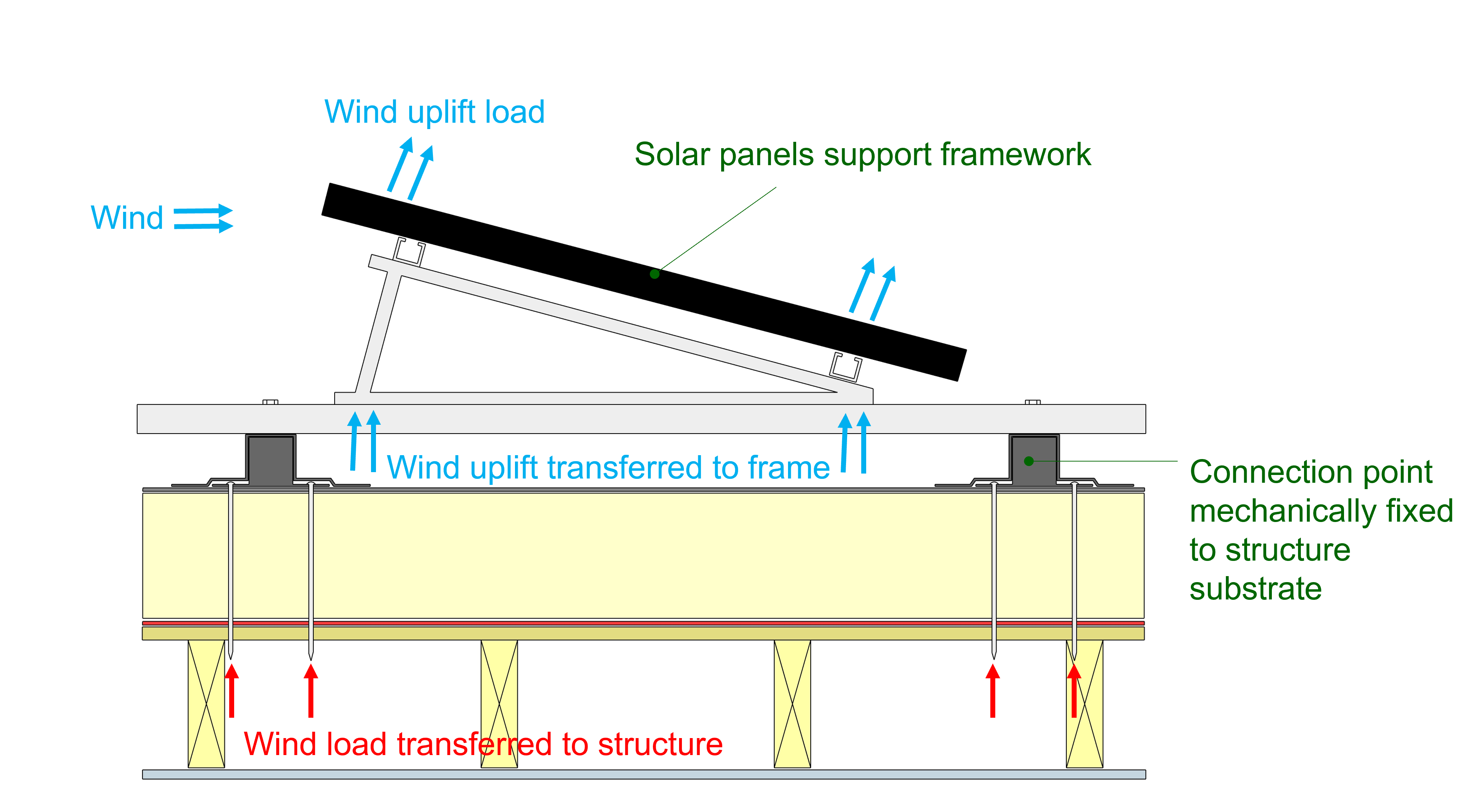

3. Mechanically fixed Installation

In a mechanically fixed installation, the solar array is attached to a fitting that has a direct connection to the building structure. All wind loads are transferred to the structure.

Advantages

Disadvantages

- Highest resistance to wind uplift

- Normally any roof pitch

- Any height building

- Any location

- RISCAuthority Document RC62 – 5.4.12 Suggests that panels should be securely fixed to structure and not held in place by ballast

- Roofing contractor required to weather/ seal in mechanical fixings

- Initial outlay more expensive due to higher installation costs

- Poor workmanship could lead to leaks

- Care needs to be taken to limit thermal bridging in warm roof constructions

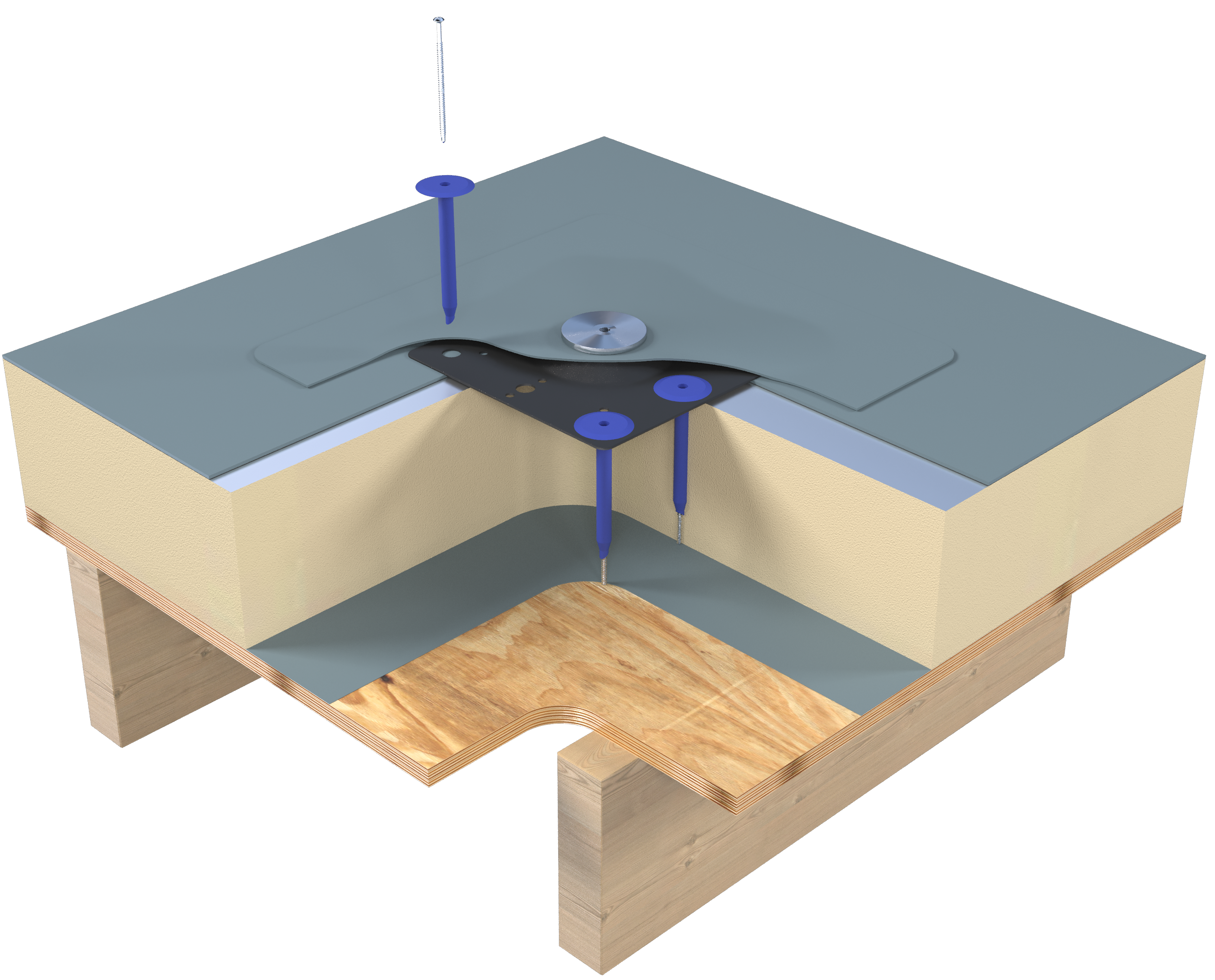

ROOFTRAK® IFP integrated fixing point

The ROOFTRAK® IFP is a product that helps to enable mechanically fixed solar installations whilst removing some of the disadvantages.

- Very high wind uplift resistance – One IFP can be equivalent to up to 500kg of ballast, but the unit only weighs 3-4 kgs

- Factory sealed unit – ROOFTRAK® IFP has patented technology that enables a piece of roofing membrane is manufactured into the product. This means no hard detailing reduces the chance of bad workmanship on-site. The installation becomes very easy and quick

- Thermally broken fixing – ROOFTRAK® IFP utilised thermally broken fixings helping to maintain the U-Value across the roof and solar installation

- Any roof construction – There are different types of IFP to accommodate nearly every type of roof construction

- Any roof membrane system – The ROOFTRAK® IFP is compatible with virtually all roof membrane systems

- Trusted by major roof membrane system manufacturers

- Peace of mind – the ROOFTRAK® IFP fixing point is warranted and has been used for over 15 years

- Compatibility – The ROOFTRAK® IFP system is compatible with virtually all solar support rail systems

- Helps to ensure installations comply with Fire Advisory RISCAuthority Document RC62

- Peace of Mind

Many roofs have solar PV mounted on them, and with the rise in energy prices and the general availability of solar technology, this trend is set to continue.

Nicholson can also provide an online product presentation containing more details around the specifics detailed in this blog. Feel free to contact us for more information

The ROOFTRAK-IFP Integrated Fixing Point system has been developed specifically around the challenging scenario of providing a connection to the building structure whilst maintaining 100% integrity of the weathering membrane. There are different fittings available to provide for most types of roof construction and the IFP system is compatible with all roofing membranes.