The construction industry has been adapting to the needs of the marketplace for decades, and in recent years we have seen an increasing importance placed on sustainability, and energy efficiency. The introduction of the Government’s Ten Point Plan for a Green Industrial Revolution sets out ambitious plans in the following ten areas.

Point 1: Advancing Offshore Wind

Point 2: Driving the Growth of Low Carbon Hydrogen

Point 3: Delivering New and Advanced Nuclear Power

Point 4: Accelerating the Shift to Zero Emission Vehicles

Point 5: Green Public Transport, Cycling and Walking

Point 6: Jet Zero and Green Ships

Point 7: Greener Buildings

Point 8: Investing in Carbon Capture, Usage and Storage

Point 9: Protecting Our Natural Environment

Point 10: Green Finance and Innovation

Greener Buildings

Point 7 highlights the need for Greener Buildings. This is great news for the environment, and great news for industry too – thousands of new jobs will be created, as well as opportunities for businesses in the supply chain. Further to this, the drive for Greener Buildings will mean exciting new opportunities for the construction sector.

The key elements here are to support the industry in future-proofing buildings and making them more energy efficient.

This means that every part of the supply chain for the construction industry can contribute to the success of this initiative, especially those with direct connections to renewable industries such as solar and heat pump technology.

Architects and designers will be able to have a positive influence on the result by selecting products that carry better green credentials and designing more energy-efficient buildings.

Off-site manufacture is leaner and less resource-heavy and produces more consistent results with less waste.

And building owners can choose to utilise renewable energy sources such as solar and wind to reduce their reliance on fossil fuels.

Sustainability at Nicholson

Innovation is at the heart of what we do at Nicholson and the drive for greener buildings has fuelled our product development in recent months. Recent updates to Document L have reinforced the need for reducing energy consumption and eliminating wastage.

With the government outlining its focus on workplaces, schools and hospitals in the commercial sector we have seen an increased demand for energy efficiency at roof level.

ROOFBOX® P

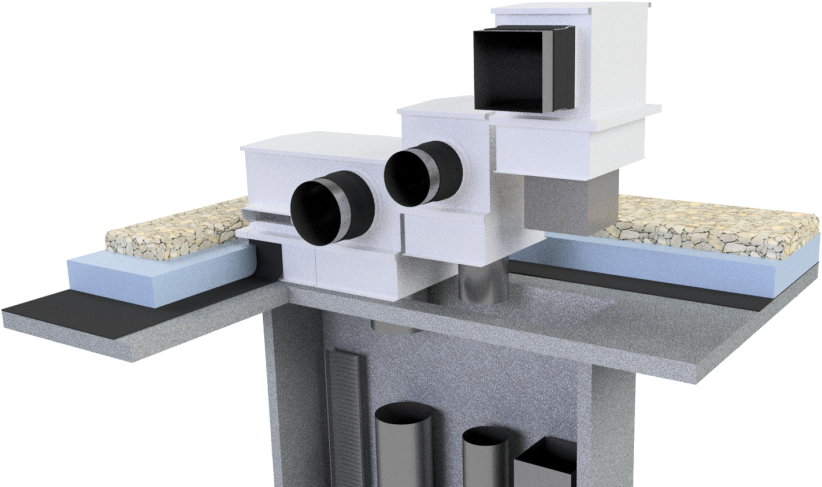

The patent-pending ROOFBOX® P is an addition to our proprietary riser-weathering system. The unique strategy deployed with the ROOFBOX® P system has sustainability in mind, bringing the following environmental benefits to any building project, including projects with high expectations regarding energy efficiency…

ROOFBOX® P provides a solution to these common carbon causing issues.

1. Airtightness

Airtightness can be defined as the resistance to inward or outward air leakage through unintentional leakage points or areas in the building envelope.

Air leaks caused by poor standards of workmanship on site can often go undetected. Over a prolonged period-of-time, this can result in constant energy losses and can create a significant increase in carbon footprint. For a long time, the detailing of service penetrations at roof level has been a challenge to achieving good airtightness in construction.

The Roofbox P system uses a carefully developed methodology that has been fully tested and certified by a UKAS approved test laboratory. By applying this methodology within a factory-controlled environment, we can ensure that every Roofbox P module is air-sealed to resist airflow when pressurised to 50 Pa.

This means that the riser-weathering solution can be air-sealed in this manner from day 1 of installation, thus aiding compliance with building air-tests. By applying proven and tested manufacturing methods in a quality-controlled factory environment, unnecessary carbon footprint caused by an air-leak can be completely avoided.

2. Avoiding waste

Another area that can lead to unnecessary carbon emissions is waste created by poor installation. Even if discovered at an early stage, this results in the burden of additional site visits, labour and materials, and the associated carbon footprint. The longer that it takes to remediate defects, the greater the impact becomes, both in expense and environmental cost.

Temporary weathering is also likely to end up being disposed to landfill, further increasing costs. If failures at roof level lead to water ingress, increased waste can be expected through loss of performance, extra expenses and replacement of defective materials.

The only satisfactory methodology to overcome this is to get it right first time with a proprietary system designed to eliminate risks of poor workmanship and site installation. The Roofbox P system provides reliable weathering from the point of installation, minimises the need for site-fitted services and is quality-controlled for performance in a factory environment. This way, the integrity of the roof is assured at every stage of the project, and the risk of failure, rework and delay is eliminated, saving cost carbon and conscience!

3. Thermal Efficiency

‘The ratio of the work done by a heat engine to the energy supplied to it.’

The efficiency of even the best heat engines is usually below 50% or more. So, the energy not utilised is a major waste of energy resources. Therefore, a thermally efficient building envelope is desirable as it reduces a building’s carbon footprint significantly.

Service penetrations can be a weak point in a building’s thermal envelope where the insulated roof build-up is interrupted at the aperture. Making the insulation good around the services is often difficult to achieve without gaps.

As a factory-insulated system, each Roofbox P module ensures a proven and consistent U-value over roof openings. With the standard U value of 0.41W/M2K and insulated ductwork sealed into the module, excellent area-weighted roof U-values can be achieved. Results can be further enhanced with additional insulation within the base layer of certain module types. Roofbox P ensures the thermal performance of the roof is maintained, keeping the building at its optimal temperature without wasted energy.

To find out more about how ROOFBOX P could benefit your projects please click here.

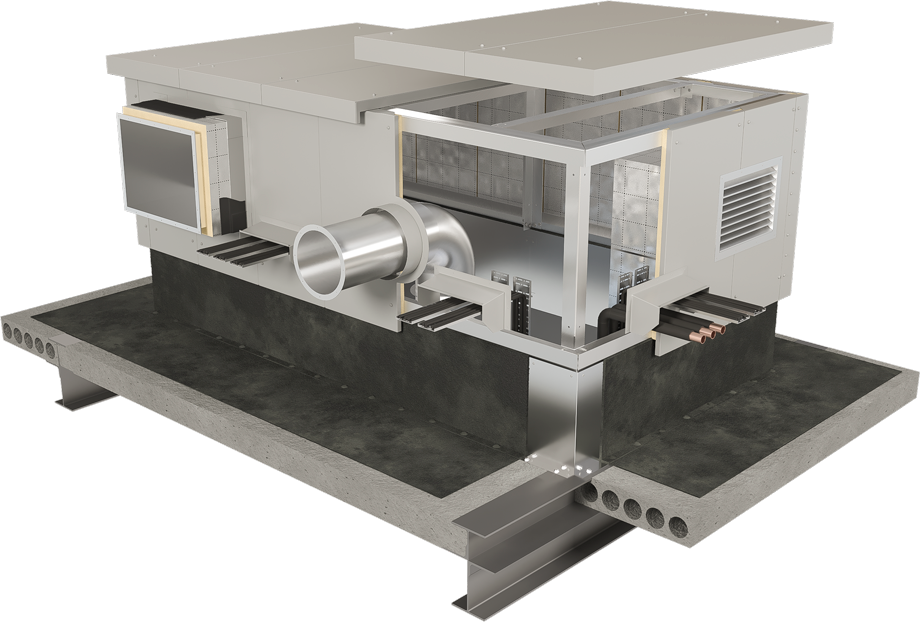

roof cabinets

The ROOFBOX® weathering system for service penetrations provides a proprietary and guaranteed solution to the inherent problems associated with bringing pipes, cables and ducts through the waterproofing layer at roof level. These insulated aluminium units are powder coated and provide an alternative to the traditional ‘dog kennel’ approach to weathering services as they exit onto the roof.